HOW TO BUILD A

FRUIT & VEGETABLE

COOLING CHAMBER

Using forced-air evaporative cooling to preserve

fruits and vegetables in hot and dry regions

Free and open-source

ABOUT

THIS EVAPORATIVE COOLING CHAMBER

FOOD SECURITY

ENTREPRENEURSHIP

SUSTAINABILITY

AFFORDABILITY

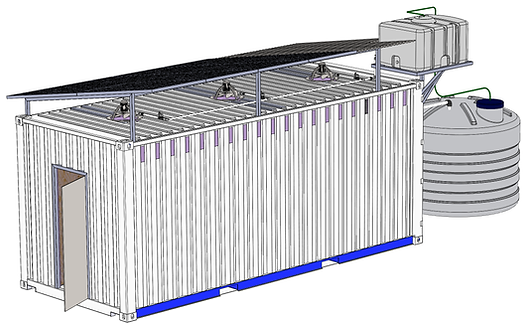

A team at MIT has designed a forced-air evaporative cooling chamber that can be built in a used shipping container. The chamber generates a cool and humid environment for produce with lower energy consumption and half the cost of refrigerated cold rooms. Designed specifically for use in hot and dry climates, the forced-air evaporative cooling chamber can be constructed for on-grid as well as off-grid settings. Detailed documentation of this open-source design can be found below.

The MIT Spinout CoolVeg Foundation was formed to commercialize this technology.

Evaporative cooling systems are particularly well-suited to hot, dry regions with some access to water and where electricity supply is limited or prohibitively expensive.

Forced-Air Evaporative Cooling Chamber

Evaporative cooling increases the humidity and reduces air temperature through an energy-efficient process. This cool humid air is then forced through stacks of crates, rapidly cooling the produce inside.

The design from the team at MIT is based on a used shipping container and is half the cost of a typical refrigerated cold room with similar capacity.

WHY

DOES THIS

MATTER?

Storing vegetables after harvest without cooling them can lead to spoilage and therefore reduced access to fresh and nutritious food and reduced income for farmers. Most techniques for cooling and storing vegetables rely on vapor-compression refrigeration, which may not be affordable or available for many smallholder farmers, particularly those living in remote, off-grid, and low-income areas.

WHAT

ARE WE

OFFERING?

Guidance for Building a Fruit and Vegetable Cooling Chamber

We offer documentation covering the materials needed, descriptions of key systems, and steps for building a forced-air evaporative cooling chamber that provides rapid pre-cooling and improved storage for fruits and vegetables.

The information and designs provided on this website and related documentation are available free of charge.

For additional information see the terms of use.

Portable and Mobile Forced-Air Evaporative Cooling Chambers

Over the past 3 years the CoolVeg team has been developing variations on the shipping container-based evaporative cooling chamber detailed on this website.

Portable forced-air evaporative

cooling chamber

Storage capacity of 25 crates (~500 kg)

Can be carried by 6 people or transported on a small truck for placement in remote areas

.jpeg)

Molbie forced-air evaporative

cooling chamber

Storage capacity of 32 crates (~640 kg)

Designed to allow fruits and vegetables to be picked up at farm gates and pre-cooled while in transit on rural roads to markets

Dr. Eric Verploegen (left) is a Research Engineer at MIT D-Lab and Founder of CoolVeg. His work focuses on evaporative cooling for fruit and vegetable preservation with ongoing projects in Mali, Niger, Kenya, Uganda, and India.

Dr. Leon Glicksman (second from left) is a Professor of Building Technology and Mechanical Engineering. He works on energy efficiency in buildings, natural ventilation, thermal insulation, and applications of such technologies in developing countries.

Dr. Daniel Sweeney (center) is a Research Scientist and Lecturer at MIT D-Lab where he leads the D-Lab Biomass Fuel & Cookstoves Group. Dan provides technical assistance to field partners and performs lab- and field-based research and development on biomass and waste conversion processes.

Heewon Lee (second from right) is an industrial designer and design educator. His work focuses on creating and facilitating design educational programs in the humanitarian and development contexts.

Nancy Adams (right) is MIT D-Lab’s Communications Officer. She is responsible for overall communications strategy for D-Lab and works closely with leadership and program staff to produce a wide variety of print and digital materials.

OUR

PARTNERS

The development of the forced-air evaporative cooling chamber was led by researchers from MIT D-Lab and MIT's Building Technology Program.

This work is made possible in part by funding from Abdul Latif Jameel Water and Food Systems Lab (J-WAFS).

Pilot chambers were constructed in partnership with Solar Freeze in Kibwezi, Kenya and Hunnarshala Foundation in Bhuj, India.

Hunnarshala Foundation is a non-for-profit organization based in Bhuj, Gujarat, working towards sustainable habitats and to establish & empower the role of Artisans in Architecture. The Hunnarshala team that is supporting this work includes:

Mr. Mahavir Acharya (left) is an engineer by training and a founding member of the Hunnarshala Foundation and Executive Director. He leads the research and innovation for energy-efficient building materials like wool insulation, evaporative cooling, and natural plasters.

Ms. Gulal Bhavsar (second from left) is an engineer with a master's in construction management. She joined Hunnarshala as a research assistant and oversees the material testing lab and works on the design of earth-based construction materials like rammed earth and stabilized adobe.

Mr. Shailesh Mohanlal Vyas (center) is a graduate from Gujarat Agriculture University with a PGD in Ecology & Environment and M.A. in Economics. He has 26 years of experience in making farming systems sustainable and adapted to the harsh climatic conditions of Kachchh district.

Solar Freeze is pioneering PAYGO cold storage units powered by solar energy for smallholder farmers, SMEs and healthcare facilities in off-grid and weak-grid areas of Kenya. The Solar Freeze team that is supporting this work includes:

Dysmus Kisilu (second from right), is the founder of Solar Freeze, a company that specializes in providing renewable energy solutions (PAYGO solar powered cold storage units) to smallholder farmers in Kenya. To date, Dysmus has worked with 3,000 smallholder farmers in Kenya.

Stephen Nyamai (right) is an independent consultant in collaboration with MIT and Solar Freeze to conduct shelf-life experiments for relevant fruits and vegetables and maintain the forced-air evaporative cooling chamber in Makueni County Kenya.

GET IN

TOUCH

Please let us know your feedback about:

-

Improvements to the documentation on this website

-

Suggested improvements to the chamber design

-

Successes and challenges with building this type of cooling chamber

-

Recommendations for where this cooling chamber could be deployed

-

Anything else...

We can't wait to hear from you!

b.png)